We satisfy the continuous evolution of the market

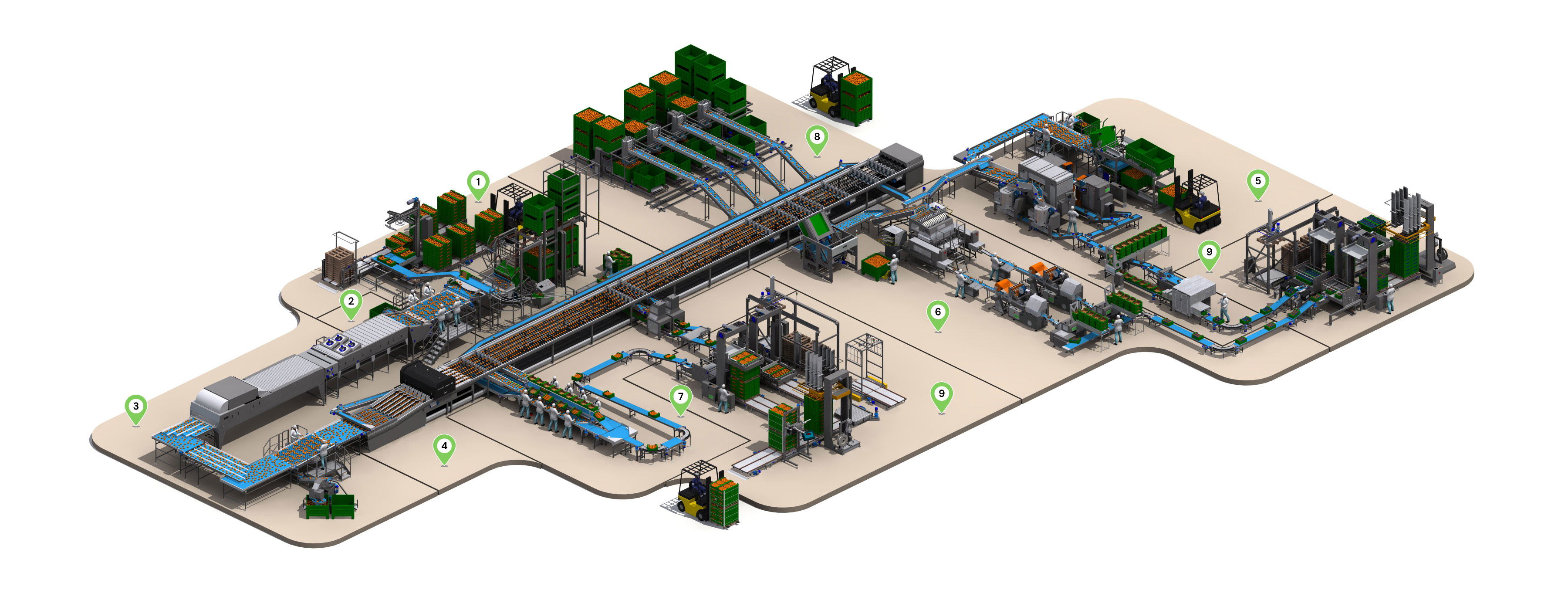

Depending on the type of product, fruits and vegetables are transferred to the working line by bins, boxes or big bags on conveyor belts or through water channels.

The pre-sorting increases the productivity of the optical sorter by eliminating all products and items not suitable for sale.

Specific treatments are required due to the high standards of hygiene, aesthetic appearance and shelf life of the product imposed by the market.

We sort products across the board, classifying them by: Internal and External Quality, Colour, Shape, Diameter, Density and Weight.

Bags are the best solution for storing, promoting and selling fruit and vegetables weighing more than half a kilo.

Punnets have always been the greatest possible choice for the packaging of all delicate fresh produce because their rigid structure protects it from damage.

Boxes are the most widely used primary packaging for the sale and transport of loose fruit and vegetables.

Bins are the most widely used primary packaging for the harvesting and storing of loose fruit and vegetables in the field.

The packaging process can only be considered complete when the boxes have been palletised and strapped properly, so that the pallets are ready for transport.

Unity makes strength. Our collectors are crucial to achieve an efficient workflow in any king of processing line.

All our tracking systems are customised and custom designed: the systems can track individual packs, boxes as well as finished bins or pallets.